One thing that we failed to foresee is the cost of 3D printing. Whenever there were some parts that seemed ambiguous to purchase or required complex and custom design, we decided we would use 3D printing to make that. However, we only realized later that 3D printing will cost a lot, given the size of the parts we’re trying to print. As such, we would have to aim for reducing the number of trials and errors of printing. Our plan is to make the design as precise as possible to work as we intend it to be. To that end, we’re carefully considering the dimensions of the parts and trying to have a concrete overall design for our parts to assemble later.

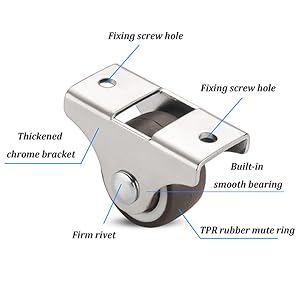

No significant changes were made to the existing design of the system. After realizing that adding too much load to the servo may draw too much current, possibly causing problems with the arduino that will be powering it through the 5V line. So, we may decide to use a weaker servo for the dispenser to draw as less power as we can from the arduino, and we are planning to add 4 caster wheels to support the weight of the machine body for spinning.

This will mean additional budget use for buying the wheels, but it is minimal, and we have not used much of the budget so far, so it will be fine.

Motor control code ended early, so Andrew will be helping with building the dispenser and case. Hopefully, the dispenser will be done earlier than we expected.

We have confirmed that the servo works fine. Additional tests will need to be done to see if the 5V power supply from the Arduino will be enough when we add load to it. Such concern was the exact reason why we decided to add wheels to the design for additional support while reducing friction.