The most significant risk that could jeopardize the project is the SDcard becoming corrupted right before the final demo. We think that we should boot up a spare, just in case it does become corrupted. No further changes were made to our design that we haven’t already mentioned. Everything is working now, except for the load cell amplifier, which we are continuing to work on.

We performed the following unit tests:

- Bluetooth messaging between client and server script

- Web socket messaging between client and server script

- Dispense button decreasing the quantity left and tracking when taken

- Servo motor moving 180 degrees, and moving it 180 degrees multiple times

- Reading “snack” weight off of load cell

- Playing speaker audio

- OAuth navigation

- Google Cal API adding correctly to your account’s google calendar

- Sending an email at specific time

- Each web app page rendered correctly on each screen size

- Accessing the web app across multiple browsers

- Dispensing pills consecutively (3+ times) on each dispensing compartment

- Email notifications are sent based on the user’s inputted timezone (not our timezone)

We performed the overall systems test:

- Clicking the dispense button dispensed a pill, moves servo, and play speaker audio

- 3 unique users, each with their own medications, cannot see or access any medication besides their own

- Adding/modifying/deleting pills and users are accurately updated in mySQL (and email notification as appropriate)

- Flowing through the web app progression with all screen sizes

Findings and design changes from tests:

- Adjusting the size of widgets on the web app, to make sure they are accessibility friendly

- Switching from Bluetooth to web sockets as bluetooth is not supported on safari

- SSL and certificate, as you could not access the web app on Chrome without this

- Installing a pipe in the dispensing compartment to avoid pills getting stuck

- Adding padding into the rotating discs to decrease their volume, as smaller pills tended to “collect” in the big disc slots

- Recording the servo motor’s position (adjusting the pill model in the web app) so it can rotate 180 clockwise, 180 counter clockwise, etc.

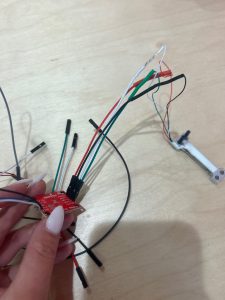

- Potentially removing the load cell amp and load cell if it continues to be noisy