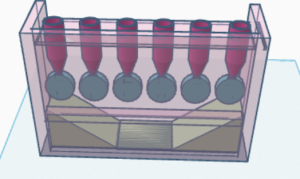

The previous week was spent refining our design in the design report where I did sections 2, 4, and 6, as well as making adjustments to our 3D printed model for the compartment and the disc. Based on feedback from the professor and TA, as well as our design requirements I made the following adjustments to our 3D model. For the compartment, the diameter at the bottom of the runner was smaller then we specified and I tried 3 different pills and only 2 of them worked as we need it to so I decided to increase the diameter by 2mm from the current 9mm to still align with the average pill size. Additionally, I made the disc slightly smaller to reduce weight and size of our components while keeping the same functionality. This will allow for a more compact design and efficient use of our budget. Then I made a model for the housing where we need to be able to mount the components. To mount the funnels, I created a holder that will be attached to the back panel of the housing and I’ve adjusted the funnel compartment to be thicker at the top so it can hold (see attached photos) and to mount the servos, I added a simple holder on the panel where the disc is for the servo motor. Since we need this panel to be specific to our 3D printed design, we will 3D print the back panel of the housing, as it will still be within budget. All the 3D printed components will finish printing this coming week and I will start focusing on the dashboard for the pills.

Aneesha’s Status Report 2/22/2025

My responsibilities this past week have been the 3D printed device and models. I adjusted the compartment design on TinkerCAD to make it a little smaller since we need six compartments and we do not want the device to be too large while still meeting our use case requirements. I put in a request for 3D printing for a single compartment and a single disc and they finished printing on Friday. I was not able to go pick them up on Friday due to my job but I will be able to either Sunday or Monday and there should be no delays. The printing did not take much time and once we verify the printed components meet our requirements, I will 3D print the rest of the components and start assembling the device. Over the next week and into spring break, I will be working on the pill-tracking dashboard as well. Currently, I am on track with the schedule that we have made.

Team Status Report 2/22/2025

This week we have made progress on finalizing hardware components and design for the device. Last week we were working on the CAD models for the components of our device we were going to 3D print, the compartments, and the disc. We have 3D printed one of each and we will go in on Sunday or Monday to pick them up and make sure they fit the amount of pills we need and are also compatible in size with the servo motors. Once we confirm that we will 3D print the rest of the models. The 3D printing was done by FabLab in TechSpark and should be well within the remainder of our budget. We have mostly been working on the design report that is due next Friday and going into thorough detail with our design based on questions and feedback we received during the presentation. All the hardware components we ordered have arrived and this week we are ready to start building the device. We will also simultaneously be working on the software components, particularly the database for tracking the pills in our compartment. In the last week, the basic app configuration and style were completed so now we will start working on the pill tracking database. Our schedule accounts for Taylor’s absence due to her surgery but she has been able to contribute a lot as she recovers. We are currently on track with our schedule.

Aneesha’s Status Report 2/15/25

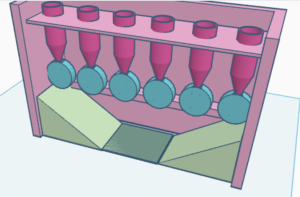

For this week, I have been working on the design slides and document. I have been working on the CAD design for the compartments of the dispensing device so we can 3D print. I made the individual designs for the pill storage and the rotating disc meant to dispense the pill based on dimension calculations that take into account average pill sizes, prevent jamming of pills, and creating an easy path for the pill from the compartments to the load cell. Then I made a 3D model of how all the components will be arranged within housing. Next week, we will be able to start 3D printing the components and I will continue to work on the physical device and the software elements that track the pills. Below is a link to all the CAD models mentioned above.

Aneesha’s Status Report for 2/8/25

This past week I have been working on the hardware design for the dispenser. I have been working with MM to get together the components that we need to order. I realized that buying the pill compartments and cutting them to fit would not be ideal for our device so I have started on a CAD design using CadQuery and TinkerCAD to design our pill compartments based on our user requirements and will continue to work on it and the hardware schematic throughout the week as well as our design document. I created a prototype and added the STL file to our GitHub repo and below is what the model will potentially look like.