Coming back from spring break, my main focus has been trying to work around the limitations that the COVID-19 pandemic poses to our fabrication. Our original plan for fabricating the controllers was to cut plywood using the TechSpark laser cutters. Now that TechSpark has fully shut down, I plan to either find an online lasercutting service, an online 3D printing service, or fabricate the controller with the limited tools I have at home (power drill). My construction material will either be plywood (still), some sort of acrylic or polycarbonate plastic that I can score and snap, or just plain perfboard.

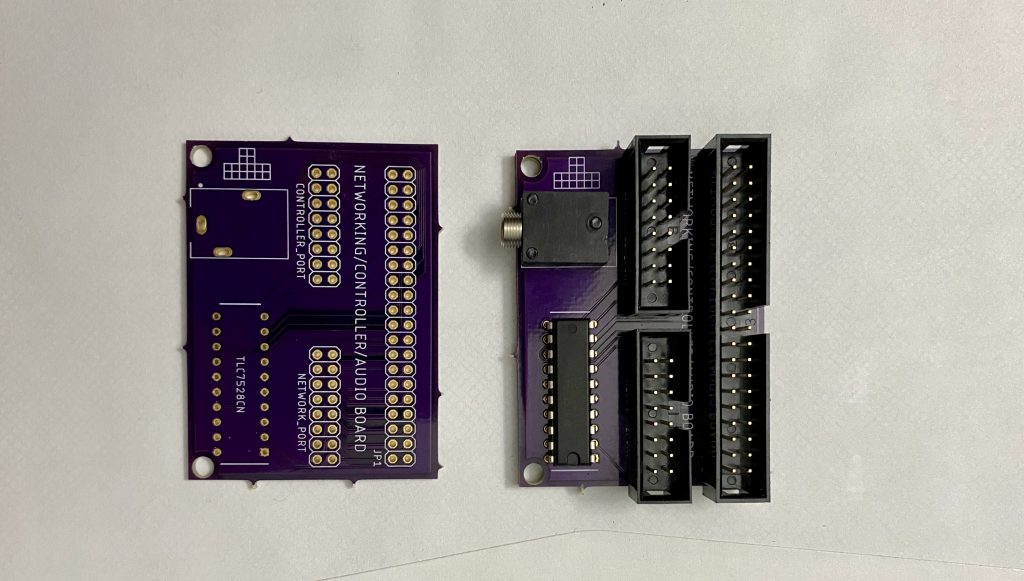

Over the break, the middleman PCBs came in from OSH Park, and the next step for them is to solder the components on. Below is a picture of the bare board as well as the board with components:

Professor Nace was kind enough to deliver the boards as well as some soldering equipment. Unfortunately, the solder from the ECE labs is lead-free, which I can’t seem to get to work. I’ve tried a range of temperatures and tip-cleaning methods but the solder just won’t flow. I’m going to get my hands on some leaded solder, either from online or shipped from home.