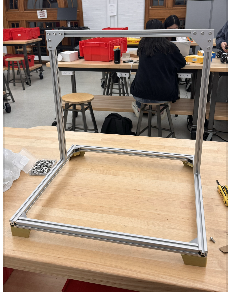

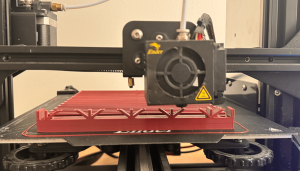

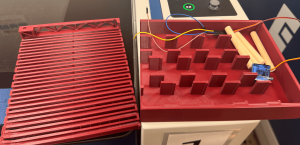

This week, we had our demo presentation. We think that our demo went pretty smoothly and the feedback we received was relatively positive. I think we need to work on getting the hardware components finished and printed so that we can connect all the pieces together to get a minimum viable product. Because I had to use the Intel NUC and not the Raspberry Pi that was given, I will need to move all the scripts and the files to the Raspberry Pi and make sure that it can communicate with the STM32 via UART. Crystal and Safiya need to continue working on the firmware and hardware components and finish cutting the dowels and complete the gantry system.

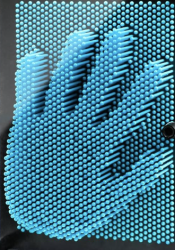

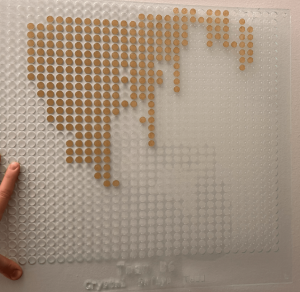

For validation, we need to do more user tests, specifically of the image that is outputted on the pin art board. We will do this by asking a bunch of people if they can see the image that is supposed to be outputted on the board. Additionally, we will do validation for the gantry system and the pin actuator system to ensure that they will push at a certain distance, given an angle. We will ensure that actuators are push pins to the intended heights 95% of the time. We will also make sure that the gantry will move down the belt consistently and with precision and accuracy.

———————————————————————————————–

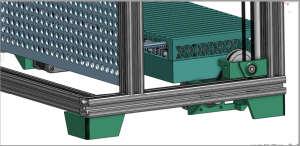

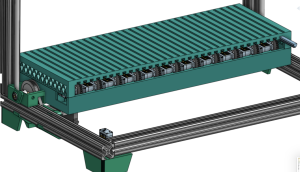

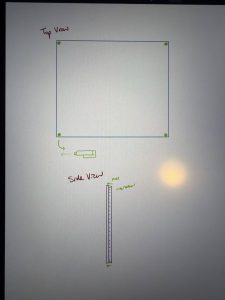

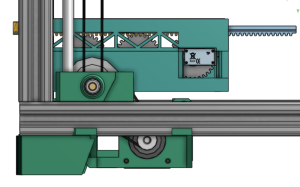

For Verification of the mechanical subgroup, we will need testing of the gantry, the pin board, and the carriage. For the gantry we will we have the carriage travel up the gantry successfully 5 times, and be reset to its limit switches at the beginning and end. We will also make sure 10 times in a row the carriage travels to the correct row that is authorized by the code.

For the carriage specifically, we will test 3 different combinations of rack and pinion motions. The test will consist of full retraction of all actuators, full extension of all actuators, and actuators at different depths.

For the pin board, we will test that all pins are stable and able to be controlled by displaying 2-3 images of varying depths and checking through 1/3 of the pins to verify a sample set that the pins are working as they should and are stabilized.

———————————————————————————————–

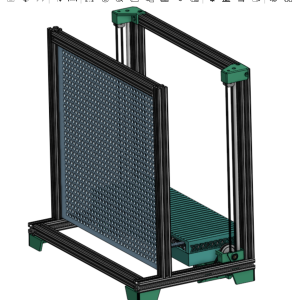

(after, V3)

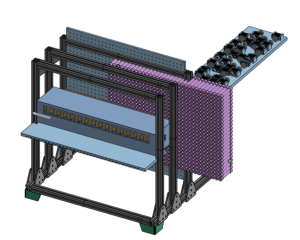

(after, V3) (before, V2)

(before, V2)