What I accomplished :

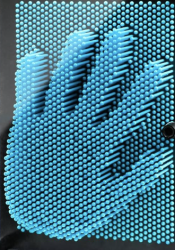

I belted the entire system and remounted the linear ball-bearing mounts. The carriage now travels up and down smoothly across the full stroke. I remounted the LivePin board at the correct spacing from the carriage. I also designed and fabricated the reset mechanism, including two custom acrylic brackets. One set to mount the linear actuators and another to hold the reset plate that clears the pins.

Needs to get done :

I need to make sure after programming is done with the 32 servos, to make sure the racks and pinions all interact properly and there are no mechanical faults. Also the final report and video need to be done, along with all servo testing.

On Track:

Yes, but with some setbacks.