Progress:

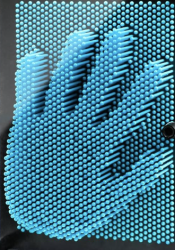

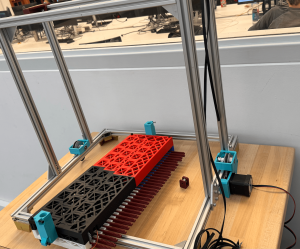

This week was a grind to finish really all the mechanical components of LivePin. I believe it is 2/3 of the way there. There were a few bumps in the design that caused me to take some more time drilling a couple holes to make the gearboxes fit, but so far I have all the 3D Printed parts other than the pinions and reprints of the feet. I was able to assemble the full frame and carriage (without servos), and am now working on the gantry, I assembled 1 out of 2 of the gearboxes and started belting it today. I superglued the bearing plates to the carriage, and am letting it set till tomorrow. I also made edits to the pin board by putting on 10 spacers.

Goals for Next Week: Handoff LivePin to programming on Tuesday at the latest. Finish testing by Sunday. This also includes smaller goals like printing all pinions by Tuesday, finish assembly of gearboxes and belts, as well as assembling the pin board.

On Schedule: Yes but rushing

Question of the Week:

Knowledge I found necessary to learn was research, design, and execution. Although tedious and at times hopeless feeling, research and designing in CAD were so crucial once I reached assembly. The time I put into a thoughtful design is now paying off as the construction comes to life and the moving parts start to fit together. Another strategy is research, I had no idea how to make a “LivePin” or a tool that goes up and down and pushes pins, so I looked for parallels and studied those. I could not find any LivePin type devices, so I looked at how 3D printers are built. That research was the basis of the design and made things work. I also learned to prioritize purchasing even when the design was not as far along as I wanted. Knowing to reprioritize was crucial.

The biggest new skill was talking to people who could help. I introduced myself to laser cutter monitors, Robo Club managers, and the machine shop manager, and they helped with both fabrication and sourcing (bolts and acrylic). Those connections were actually fun and very useful for reality checks. For example, I was ready to 3D print 1,024 pins until a TechSpark woodworker suggested using dowels instead, which saved time and money. These are the strategies I am keeping: Research and design (thoroughly), use your available resources, and learn to reprioritize when necessary.