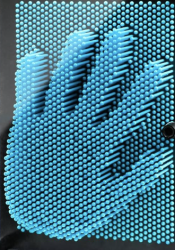

This week I pushed purchasing and fabrication forward. I submitted all purchase requests for the frame and motion system, revised the cart to swap in cheaper equivalents, and removed a few non-essential frame parts to stay in budget. I also brought my 3D printer back online and printed a first rack-and-pinion set, the print has defects, so I started tuning the printer. On the pin board, I went to TechSpark planning to laser cut but they didn’t have the right sheet size. I checked Ideate and confirmed they have acrylic that fits. Back on CAD, I re-checked cost and realized 1,024 dowels would strain the budget, so I explored alternatives: bulk chopsticks were cheap but too small in diameter, at Robo Club I found PVC stock that could work. I contacted the shop manager to request material.

I’m generally on schedule for frame and motion procurement, but the pin board is waiting on final material choice. To stay on track, I will finalize the pin diameter and hole pattern as soon as I hear back on the PVC, size the laser files accordingly, and cut at Ideate. In parallel I’ll finish the printer tuning and re-print the rack and pinion so mechanical tests are not blocked.

My Goals:

Finalize pin-board design with confirmed pin material and diameter, plus laser ready DXF.

Pin board laser-cut at Ideate and a small assembled section for testing.

Reprint, clean rack-and-pinion set and a short note on print settings and tolerances.

Updated BOM with actual unit prices from the approved frame/motion orders and removal of the unused components.