Category: Ethan’s Status Reports

Ethan’s Status Report for 12/6

It is crunch time. This week I spent the most amount of time and accomplished the most on the project. Starting before the break I worked on the final presentation slides and did some small tweaks to the MVP pipeline code which included splitting the PDFs to the gantry size and sending the gcode to the motors. Then after Thanksgiving break, I worked early in the week on some physical optimizations to the physical hardware such as perfecting the lengths of the belts for the wheels and doing some wire management (hopefully more to come). Additionally I made more changes to the software pipeline such as fixing bugs with the splitting calculations, optimizing the gcode pathing algorithm, and cleaning up the website. I also helped with moving the code from our local computer to be hosted on the Raspberry Pi. Now the project is functional. There are still a few changes that can be made before demo day such as some hardware to limit the vibrations of the gantry and some extra UI/UX for the website, but the MVP is finished.

Next week, I will wrap up the project with the video, final website changes, and report.

Ethan’s Status Report for 11/22

This week the pressure was on to make lots of progress on the project. I spent most of the week fabricating the structure for the gantry. On Monday, I planned and cut the parts for the wooden board that will hold the gantry vertically. Then later in the week the entire group built the rest of the structure. This entailed drilling holes and attaching the wheel servo mounts, attaching the wheels via glue and timing belt, and attaching the gantry in place. Then on Saturday I worked on the software pipeline. This is currently our largest bottle neck since a lot of the libraries cannot create optimal svg or gcode. We’ve modified our approach to convert to a .png since it converts using the pixels for better readability, but this means that it will take a lot longer to draw if code is trying to recreate each pixel. I’ve tried multiple approaches including pre-processing using computer vision and post processing using some optimization libraries, none of which I have had much success with. I will look to continue working on this problem as well as make some minor mechanical changes to the system early next week.

After settling on the project idea back in September, I realized that I did not have much experience with any of the technologies that we were going to use for our project. Over the course of the past few months I’ve learned a lot about robotics, machine learning, and mechanics. Specifically, learning more about fabrication (3D printing, laser cutting) and different types of libraries that were relevant to the project. Often this learning was done by talking to people such as the Techspark student workers who were very gracious to give me suggestions on how to turn some of our structural ideas into reality. On the software side, I learned mostly through reading documentation perusing forums and chatrooms to see what approaches others had taken to achieve a similar outcome.

Ethan’s Status Report for 11/15

The only work I did early in the week was prepare for the interim demos. This included making a list of talking points and details that I wanted to share with the instruction staff. This work was not particularly difficult or time consuming, but it was necessary to ensure I remained within the demo time limit while conveying all the necessary information.

In the back half of the week the team started getting in parts necessary for the structure of the gantry. On Friday, Andrew and myself were able to increase the length of the gantry with the new 1200mm rods. The reason for this change was highlighted in last week’s team report. Additionally, the prefabricated cart arrived which allowed everyone to start planning how to attach our gantry securely to the cart. More details on this in this weeks team report.

Looking forward to next week, I want to be able to finish the structure with the gantry on it. This will allow us to start testing the wheels and the pdf splicing software.

Ethan’s Status Report for 11/8

This week I played a lot of catchup in preparation for the interim demo. Early in the week I finished 3D printing the necessary parts and helped Andrew assemble some of the gantry. The gantry assembly was finished on Wednesday, which allowed me to test the PDF to SVG file converter that I started this week. Then I integrated Andrew’s local host website on the Flask server with my converted to allow for PDF uploads to the site and convert them to SVG automatically. The original intention was to host the site and do the SVG conversion on the Raspberry Pi 5, but we had some hiccups connecting to the Pi which needs some further evaluation. This means I had to change our approach for the demo and make the code be able to work on one of our team members’ computers instead.

Looking forward to next week, assuming the interim demo goes as planned, I will make changes to the existing gantry design. For the demo we plan to have the gantry functional horizontally so some modified parts are required for vertical drawing. Additionally, I want to order the parts for the structure which can hopefully arrive and start assembly in the back half of the week or the start of the week after.

Ethan’s Status Report for 11/1

This week did not go to plan. I acquired the 3D printed parts along with the laser cut parts I made last week. However, upon starting the construction of the gantry we ran into some issues. Notably the laser cut parts did not fit with the 3D printed parts. Therefore, we had to pivot back to 3D printed parts. This means we had to place an order for 3D printer filament which arrived very late in the week. That same day I started printing some of the parts that needed to be replaced. However, this is very time consuming since Techspark only has one 3D printer that can be used if you bring your own filament. Therefore, I had to strategically print batches such that the printer was going over night. At the time of this post 5 of 7 of the necessary parts are printed. Therefore, assuming no other hiccups the construction will be done on Monday. This allows for us to have enough time to test our code on the gantry for interim demo.

Looking toward next week I will be finish 3D printing the rest of the necessary parts and assemble the gantry. Then I will switch over to the software side in order to prepare for the demo. I will also order the parts for the structure once the gantry is assembled.

Ethan’s Status Report for 10/25

Once again, I was not able to get as much done as I wanted this week. My primary goal was to fully construct the gantry system, however I ran in to a few obstacles. The primary setback was finding out that 3D printing some gantry at Techspark was expensive and that I needed to find an alternative. I was able to pivot and laser cut some of the 3D printed pieces using plywood in the later part of the week (with the help of Andrew), but not after using a faulty laser cutter, wasting material and budget. Additionally, some of the parts are required to be 3D printed so Alex and I were able to find a friend who was willing to 3D print the parts for us for no cost, but they would not be ready until Sunday (10/26) at the earliest.

At this point, I am behind schedule. It was planned that the construction of the gantry system would be complete this week. However, assuming I can get the 3D printed parts early next week, I think it is possible to complete the gantry system construction and move on to the software side of the project while beginning to purchase the base and structure that will house the gantry.

Ethan’s Status Report for 10/18

This week was once again a slower week in terms of personal progress due to being right after the design presentations. However, the feedback from the presentations was valuable. This motivated the work I did this week which included ordering of gantry parts, ideating a new, less expensive wheel based system for the gantry stand, and completing the Design Report.

Previously the team scrapped the wheels to due the cost for our original design being too high, but the new design uses a pre-fabed, low cost metal wagon that we are going to modify (more details in this weeks team report). Therefore, I will have to modify the CAD to account for the changes to the design once we get them finalized and approved by the teaching staff.

This sets me up to start 3D printing parts and assembling the gantry the week after break. Additionally, with the changes to the gantry stand, I may start ordering the stand parts and modifying the CAD if the feedback from the teaching staff about the change is positive.

Ethan’s Status Report for 10/4

This week was a slower week in terms of personal progress, due to a variety of factors. One such factor was that I was expecting feedback on our design presentation to incorporate into my structural design and design report, but I have not received feedback yet. As a result, this has caused some delay in my part ordering, structural design changes, and design report writing.

Despite those challenges I was able to start some work on two of the three tasks above. Firstly, I was able to put in some part orders for parts for the gantry. The gantry is an existing design (https://www.instructables.com/4xiDraw/) that we are going to attach to our uniquely designed stand. Therefore, the parts needed are very unlikely to change. Secondly, I was able to start work on the design report by working on the sections I have been in charge of thus far: the structure. This includes the implementation plan as well as the overall design. This work was minimal as I don’t want to get too far without feedback from the course staff after our presentation.

Looking forward to next week, I hope to get the material I ordered and start the assembly of the gantry. This includes planning out 3D printed parts and fully fleshing out the structure implementation plan which goes along with finishing the design report. This differs a little bit from our original task distribution which had me working more on the software side. However, as the project has progressed and I’ve done most of the work on the structure, I have been leading that portion and Andrew has been working more on the software.

Ethan’s Status Report for 9/27

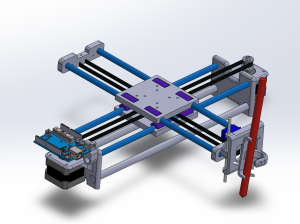

This week I was mostly focused on making the computer aided design (CAD) for the structure of our gantry. We are using an existing gantry design (https://www.instructables.com/4xiDraw/), but we need to create our own structure design so that our gantry is portable and has the capability to raise and lower.

Shown below is the existing gantry.

From our original BOM from last week, I created the below preliminary model.

However, upon updating our BOM during the middle of the week with extra materials that we forgot, we realized that we were over budget and opted to remove the wheels from our original design for reasons outlined in the Team Status Report for 9/27. This led us to our current design shown below.

Looking forward to next week, I look to gain feedback on the structure design during our Design Presentation and incorporate it into the next and final version of the CAD model. Then when the CAD is finalized I look to order the parts and start 3D printing gantry parts and cutting the ordered parts to size.