After last week’s presentations, we wanted to incorporate the some of the feedback we received. Firstly, we decided that some of our requirements we somewhat unreasonable such as having 95% accuracy and precision for drawing strokes. We reevaluated some of these requirements and decided on figures that were reasonable and justifiable.

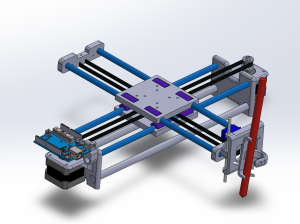

Next we finalized our bill of materials (BOM) and while doing so we realized that we were going to be overbudget. The primary source of our spending is on structural and mechanical parts such as motors, rails, and wheels. In order to maintain the most functionality we decided to remove the wheels and the automatic horizontal adjustment functionality from our design for the following reasons:

- We plan to showcase our design on the moveable whiteboards found in the 1300 hallway of Hamershlag Hall. These boards are much taller than they are wide. Therefore during our final presentation it would be unlikely that we’d be able to showcase the automatic horizontal movement.

- Re-adding the wheels/horizontal movement would be a lot easier than trying to re-add rails/vertical movement. In the case where we end up under budget, it would be impossible to add the rails at a later date. However, wheels could be added later as they would be attached to the existing structure with only minimal changes.

Our final change this week was ditching the ultra sonic sensors used for dynamic dimension allotment. We decided that adding the sensors would be too bulky and a better alternative could be a basic monochrome camera which detects lines drawn by the user as bounds. However, we are still determining if this idea is worth implementing now that we no longer have horizontal functionality.

Looking toward next week, we plan to work on the following:

- Finish the website where the user will upload their PDF

- Get feedback from the Design Presentation to incorporate into our requirements and structure

- Place the remaining orders for materials on our BOM

Below are our answers to the questions outlined on Status Report 2:

A was written by Andrew

Our project is designed with user safety in mind. Since it involves motors and other moving parts on the gantry system, we are ensuring that those components are shielded or enclosed to prevent accidental injury during operation. The system will be designed so that users do not need to physically interact with the gantry once it begins drawing, minimizing the risk of harm. Our project will be used for teaching, presenting, and collaborating. It reduces the time and effort required to manually copy diagrams onto a whiteboard which makes tasks less tedious and more reliable. It also gives users the chance for make quick edits. From the welfare perspective, this contributes to user well-being by streamlining preparation and letting people focus on the task at hand such as teaching rather than on repetitive manual work.

B was written by Alex

The robot particularly helps support teachers and students by automating the whiteboard writing process. This could help support underfunded schools by giving them access to a technology similar to smartboards or projectors that they may be unable to afford. It’s a mostly lower cost design that could be used throughout a building. These underfunded schools are often home to communities that are often underserved or underrepresented. It can also help aid in communication, as the whiteboard medium is one of collaboration, and this device would only make that easier.

C was written by Ethan.

We designed our project to be customizable and usable anywhere. Specifically we were targeting school teachers. This could have economic implications as we envisioned our project to be used on any type of whiteboard. Therefore schools would only need one gantry system that could be shared in the building. This would ultimately save money in schools since teachers would be more productive and thus a higher percentage of their salary would be spent on teaching. This could have a similar economic impact in other industries if used before meetings to save the setup time for the presenter.