This week’s focus for us was to incorporate the feedback we received from the design presentation. We decided to refine our system design. The significant thing that we decided to change was adding the wheels back into our gantry design so our gantry can move horizontally. Before this week, we had taken out the wheels since we had a budget constraint. After some research, we potentially found a more affordable option by using a premade wagon base.

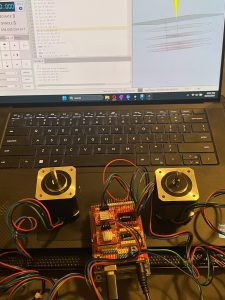

Progress was made on both software and hardware this week as well. On the software side, we continued to work on the file upload and parsing. We were able to continue testing the PDF conversion to G-code. On the hardware side, the part orders were finalized and we began preparing for motor setup and control testing. Most of the ordered components have arrived. As a result, next week will focus heavily on system integration.

We plan to get the motors running. We will also begin integrating the software upload with the hardware control system to start full end-to-end testing. While we’re slightly behind schedule due to the design revisions, but hopefully the updated plan puts us in good position to catch up quickly.

Part A was written by Alex

Our project has the potential to create impact on a global scale. For one, it has potential for use in any academic institution around the world. The technology would be easily adaptable and can theoretically transcribe any PDF, meaning regardless of language or location, it would still work. It is also cheaper and more transportable than the systems it replaces, like classroom projectors. It also integrates well with whiteboards or chalkboards, which are common around the world. We also hope to make it easy to use, meaning anyone, even those with limited technical knowledge should be able to make use of it.

Part B was written by Ethan

The project at a glance does not seem to have any major cultural considerations, but even at a small scale any sort of automation can have a cultural impact as to some extent, someone’s job is being done by a machine. Our intentions with the project is not to automate someone’s job, but instead be a tool to help teachers, presenters, and companies focus on the important parts involving putting text or diagrams on a whiteboard, getting the their point across and having the content being easily editable.

From a larger perspective this project strengthens the wider movement of automation in many aspects of industry. The subject of automation is still quite divisive to many, and our project further encourages using machines and to an extent, robots, in front of a very impressionable group, children.

Part C was written by Andrew

From an environmental standpoint, our gantry will be drawing directly on whiteboards and other reusable surfaces, in classrooms and meeting spaces, so that means there’s no need to use paper copies of diagrams, which helps reduce paper waste over time. The hardware also runs on low power with the Raspberry Pi and Arduino using potentially less energy than a projector would. We also will be 3D printing some of our own parts in Techspark which helps limit shipping and packaging waste.