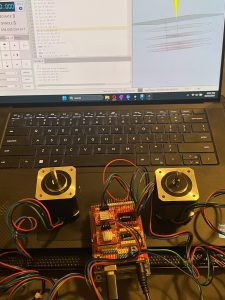

This week was full on integration. Right after Thanksgiving break, I started writing and debugging our software pipeline. I tested and fixed the Arduino movement code to ensure it moved the right distance every time. I also worked on the PDF to PNG to slices of GCode. I helped our team go from hopes and dreams of a functioning project to a fully operational system. I got the gantry working reliably, able to cover the full area by fixing our code and messing with some of the config. This also involved editing the GRBL firmware so we could enable soft limits without the ability to home with limit switches. I also programmed it to automatically move forward after finishing a section, so it can cover the entire whiteboard autonomously. Yesterday I started trying to optimize our G-code output, but Ethan was the one able to successfully complete that task. Today I moved our entire pipeline over to the Raspberry Pi, so everything can be controlled remotely over the website.

We are currently on schedule, the system integration is essentially complete, with just a few optional avenues for improvement tomorrow before the demo. I also plan on testing the system tomorrow and before the demo Monday to ensure reliability. The rest of the week I will be working on the video submission and final project writeup.