Accomplishments

This week, I worked with Caitlyn and Nick on user tests. We conducted multiple user tests and had them fill out feedback surveys on intuitiveness of the Kar and the haptic feedback. While we did some of these user tests, we noticed multiple bugs. For example: the Kar would keep running after Bluetooth disconnected, the BLE supervision timeout would be too high (and therefore the Kar would keep running for a while after it disconnected from the Kontroller), and the Kontroller wouldn’t reconnect/try to scan to connect to the Kar after a reset was triggered on either device. We addressed all of these issues, and we will continue polishing our system until demo day.

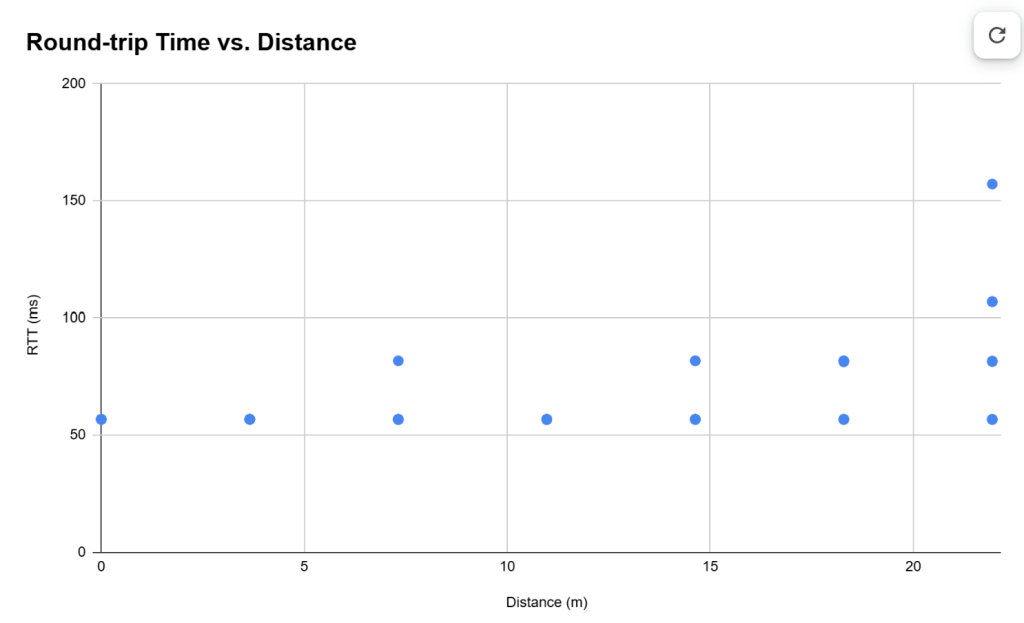

Finally, we conducted some BLE roundtrip and end-to-end latency tests. We met our end-to-end latency target of <50 ms. Here is a graph further showing our round-trip latency. Of course, there is some variance with latency as distance between the BLE devices increases, but the connection and latency of packets is reliable for a distance within 10 m.

Progress / Schedule

We have reached our MVP. We are now adding finishing touches, and polishing as much as possible before our demo day.

Next Steps

- Perform more user testing and collect more feedback.

- Fine-tune Kar reverse movement and program switch for reverse motion.