Part A: Nick (public health, safety or welfare)

The one major health/safety concern for our product is the concern of a haywire car driving around without control. In order to address this, we are implementing engineering solutions to ensure this will not occur. The three major solutions we are planning are 1) keeping the Kar in an enclosure will doing our demo, 2) allowing a user to easily put the Kar in a stopped idle mode, and 3) implementing timeouts between the glove microcontroller and the Kar such that if there is no communication between the two over a certain length of time, the Kar automatically switches into its idle mode. We believe these solutions will be sufficient to ensure Kar safety at all times.

Part B: Caitlyn (social factors):

Our glove controller and kar meets the need for more natural and immersive interaction by allowing people to drive a kart directly with their hand movements. Unlike a 2D driving video game, the experience is physical and tangible, enabling the user to feel the kar’s motion rather than only seeing it on screen. Compared to an RC kar with a traditional controller, the glove is more intuitive and inclusive, since it removes the learning curve of joysticks or buttons, allowing anyone to pick it up quickly. This project lowers the barriers to driving RC kars for everyone, making it more accessible, engaging, and fun. It also supports community interests in interactive driving, collaboration, and friendly competition.

Part C: Enrique (Economic Factors)

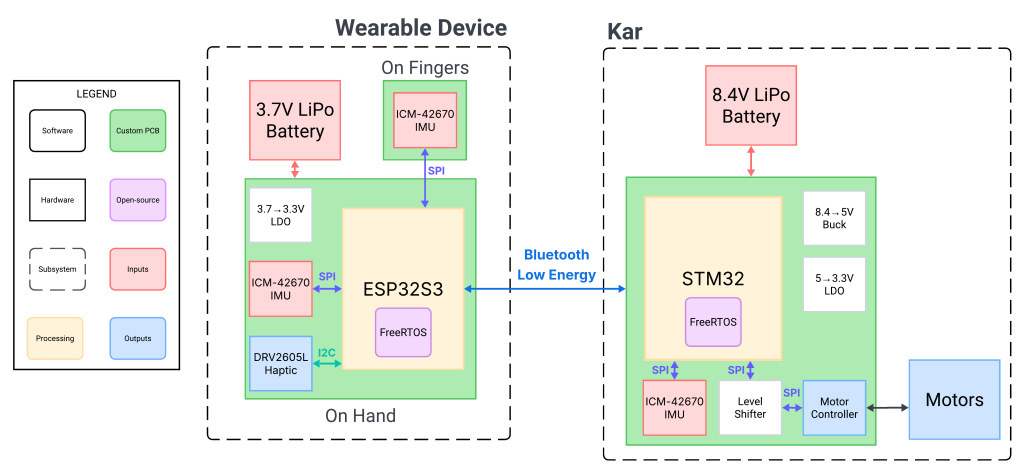

Our Mario Kar system balances performance and affordability by leveraging widely available microcontrollers (ESP32 and STM32) and low-cost IMU sensors. These components are mass-produced, making them economically viable for both prototyping and potential scaling. Using Bluetooth as the communication channel avoids the need for specialized hardware and reduces distribution costs, since wireless modules are integrated into the ESP32. From a consumption perspective, the design is energy-efficient and powered by inexpensive batteries, minimizing recurring costs for users. Overall, the project demonstrates how accessible embedded hardware and open-source software can be combined to deliver an interactive system that is both technically capable and economically practical.

——————————————————————————–

Nick wrote section A, Caitlyn wrote section B, and Enrique wrote section C.

——————————————————————————–

Progress

- Worked on the Design Presentation, which addresses how use-case requirements will be addressed through design requirements. Also designed out the system-wide and individual subsystem architectures and flows.

- Purchased multiple components, such as the DonkeyCar for PCB layout and microcontrollers for initial prototyping and breadboarding.

- Setup FreeRTOS on the ESP32-S3 and STM32 Nucleo board and began setting up development workflow.

- Completed the component selection, schematic, and layout for both the glove/controller and kar PCBs.

Design Changes

- Beyond our MVP, one of our stretch goals is to add a first-person camera to the kar. However, if we continue using Bluetooth or Bluetooth LE for communication between the controller and the kar, receiving the camera feed may be difficult. Therefore, we may need to reconsider our current communication methods to support future camera integration.

Risks & Risk Management

- An ongoing risk is meeting our use-case requirement of 30–50 ms round-trip latency between the glove controller and the kar. This latency includes sampling IMU measurements, transmitting them over Bluetooth to the kar, mapping them to movements, and sending haptic feedback back to the controller. The main challenges lie in the IMU sampling frequency on both devices and the reliability of Bluetooth communication in both directions. We can mitigate this risk by optimizing IMU sampling rates, minimizing Bluetooth packets, and exploring more efficient communication protocols.