Accomplishments

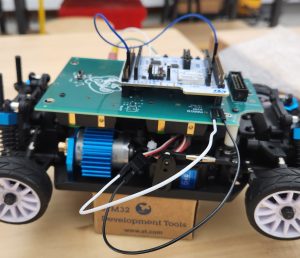

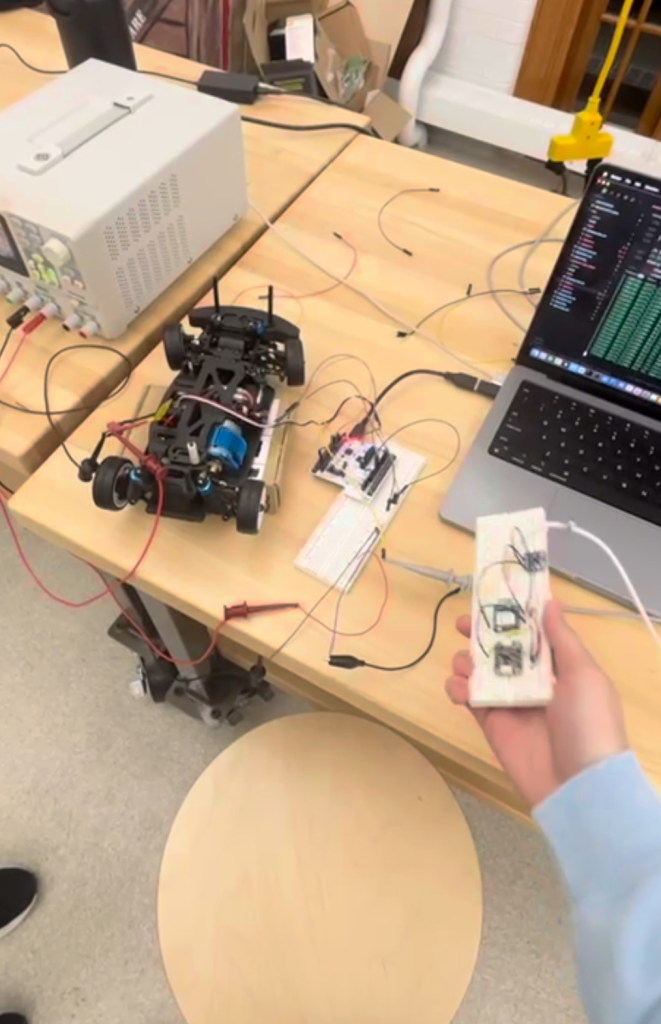

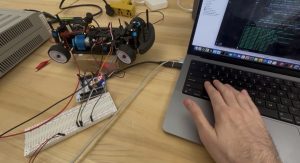

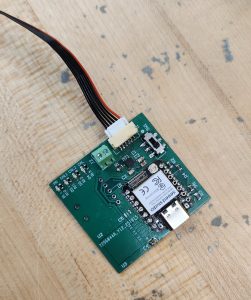

This week I primarily worked on fine tuning the speed control on the Kontroller and getting the Kar IMU (BNO005) to work for haptic motor data on the glove. Caitlyn and I completed a logarithmic mapping between the finger angle and PWM value. Fine tuning the parameters for this logarithmic relationship helped us eliminate the range of the speed “deadzone” (where the Kar is in the resting/brake position) and increase the range corresponding to PWM values that will result in significant acceleration of the Kar. Additionally, we were able to configure a new IMU for the Kar that communicates with the STM32 via I2C. This will be crucial for crash detection and sending haptic feedback to the Kontroller. Currently we are simply redirecting the gyro/acceleration values to UART. However, the next step would be to send a haptic vibration flag over BLE when high jerk (high change in acceleration over time) and gyro spikes are detected (which could likely indicate a crash).

Progress / Schedule

We’re on track for the most part. I was hoping to test the total latency of sending Kar motion commands over BLE this week but I was not able to. Early this week, I will be doing that using my camera’s slow motion feature and blinking an LED.

Next Steps / Deliverables

Besides measuring latency of commands, I will work with Caitlyn to wrap up the haptic feedback integration. I will also continue fine tuning angle to PWM conversion by experimenting with different parameters, and hopefully conduct some user tests to gauge the opinion of others’ on the user inferface.