Accomplishments

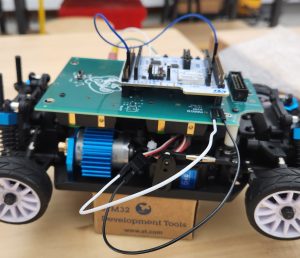

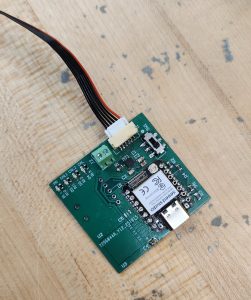

This week I worked on completing the preliminary schematic for the both the glove and the kar. This primarily involved doing component selection for the different aspects of each system. For example, the kar needed a motor controller IC for the BDC motors on the COTS RC body we are purchasing. For this, I selected TI’s DRV8242-Q1, as it does all the required current sensing and has all the needed H-bridge circuitry internally. However, this necessitated the use of a level-shifter IC, as the DRV84242 has a 5V logic level and the STM32WB55 we are using only supports 3.3V logic levels. In terms of power supply, I also had to select voltage regulators as the battery inputs we are using provide 8.4V and the motor controller and the STM32 will need 5V and 3.3V as described. I decided to use a buck converter to drop from 8.4V to 5V for the greater efficiency at the higher motor driver amperage, and then a 5V to 3.3V LDO for providing a low noise input for the STM32. The ESP32 needs to step 3.7V down to 3.3V. At low amperage, the 5V to 3.3V LDO I have selected (LM3940) has a low enough dropout voltage that it can effectively regulate for the ESP32 as well, which is convenient. After performing component selection, creating the schematic in Altium for all the components was relatively straightforward. The one component I have not yet selected + put in schematic is the IMU, as the team is still discussing regarding IMU selection and/or the usage of a flex sensor in the control glove.

Progress/Schedule

Due to not having selected an IMU, my progress is slightly behind schedule. However, I am confident I can quickly select the IMU and put it in schematic at the start of next week, and continue with my tasks as normal.

Next Steps

As described, this coming week I will be selecting the IMU and doing the schematic for it to catch up to the schedule. Additionally, I will start work on the layout for the PCBs as described in our gantt chart. By next Saturday, I should have preliminary schematic and layout prepared for review.