This week, we did a bit of testing with the constructed prototypes.

The printed sensor box is a bit too small to house the sensors in the way we want it to, but we should be able to get a lot of mileage out of this prototype for testing.

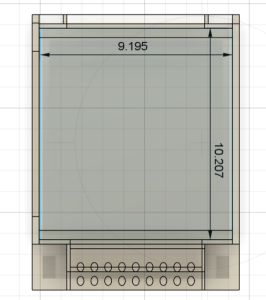

I made adjustments to and resized the sensor cavity 3D model for proper mounting.

In addition, we tested the fitting for the prototype inserts and I am working on the second iteration of the main box inserts.

I plan to laser cut the adjusted shape and test it to see how it fares.

Again, the main box of the Visor is too large to be 3D printed in one piece as it is larger than the printer’s print bed. Since we found that we can cut the model and add connectors in the setup stage right before sending the file to the 3D printer, this shouldn’t be a large problem, especially if we are going to be coating the Visor for weather proofing, which should help strengthen the connection point. I will be working with lasercut prototypes in the meantime until the team and I determine the side for the lid and hardware mounting.

The other large task to get done this week was the Design Report. For the Report, I was tasked with writing the bulk of the Introduction, the Use Case Requirements, and the Architecture and/or Principle of Operation sections.

My progress is a bit behind. I will be pushing back the actual printing and weatherproofing of the Visor until we iron out the design of the whole of it. I hope to solidify the design and dimensions of the air dams (specifically the shape and size of the gear teeth), the specifics for mounting, and the opening/closure mechanism in the coming week.

Next week, I plan to test the updated insert with the POGOH bikes. Once the design and dimensions are set, I can keep working on the 3D model for printing and testing.

0 Comments