This week, our parts arrived and we were able to continue to make progress on the hardware side of our project.

Our team met with both Sofiya Filippova, who worked on a project similar to ours during her time at BU, and Professor Michael Taylor, whose thesis was on low cost air quality sensor calibration. Sofiya gave us advice on where she and her team struggled and excelled. Professor Taylor gave us better insight into how the air quality sensors work, places where we’d need to be careful of when working with such sensors, and a few different ways in which we could test the sensors that we hadn’t thought of before. I compiled notes for our team’s meetings (with each other as well as with the people we reached out to) so that we can look back at them for reference.

Additionally, I took measurements of the POGOH Bike Basket over the weekend, and started 3D modeling the prototype sensor box.

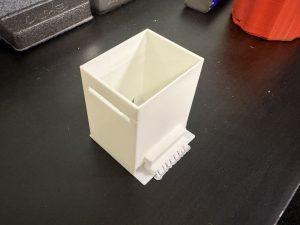

I first created a rough lasercut prototype of the main Visor cavity so that the team and I could get a better spacial understanding of how much space we have for housing all our electronics. Then, I 3D printed the prototype sensor cavity.

I believe our progress is on schedule and now that we have our parts, we will be able to progress faster.

Next week, I plan to make adjustments to the 3D models based on our testing with the current physical prototypes.

0 Comments