General update

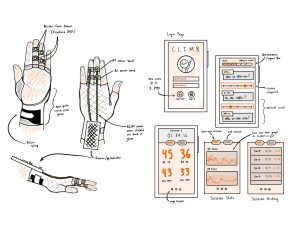

- This week we were able to test the A301-100 sensor and identify that it will be a viable component for our product, further testing is required. We also have performed research into the biomechanics of our device in regards to sensor placement. We also performed a design review and worked on a presentation desribing our review.

POtential risks and risk management

- We plan to use the 316040001 vibration motor as the haptic for our system. In the case where this motor is too aggressive or too subtle, we may need to redesign the alarm of our system. In this case, we will utilize another method of alarm via noise, or search for more suitable motors. Other factors that will influence this potential redesign are motor current and supply voltage, as our system will limited on resources. We will perform a trade-off analysis of our options accordingly to determine the choice.

Overall design changes

- Based on the results of our sensor testing this week, no design changes will be necessary. Next week, the haptic sensors will come in and we will determine if they will be suitable for our device.

Initial Schedule

-

No updates have been made to our schedule, we remain on schedule as of this status report.

CLIMB Gantt chart

Additional Week-specific Items

Part A (Alexander)

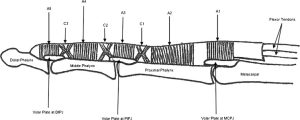

Our product is designed with one goal in mind: to ensure the personal safety of climbers. This applies to both the mental and physical well being of the user. Since our product aims to help climbers prevent and rehabilitate from pulley injuries, there are several clear health, safety and welfare considerations that we made. Pulley injuries can be (and often are) incredibly painful, especially when they are severe Grade III or Grade IV ruptures, which are injuries in which the pulley itself is fully disconnected from the tendon. Recovery from these injuries requires surgery and months of rehabilitation and is a significant detriment to the victim’s overall health and wellbeing. Since our product is an injury prevention device, it will be beneficial to the safety of climbers who use it. An additional use case for which it can be used is in the rehabilitation of climbers who have suffered a pulley injury. As they ease back into climbing with partial physical ability, our device aims to be able to set lower thresholds so that the climber can avoid reinjuring themselves, thus ensuring their physical safety and wellbeing as they recover.

There are also several psychological considerations we made in the course of designing our product. By having a device which will alarm users when they are approaching dangerous force distributions on their fingers, users who are anxious about climbing can have assurance that they will be physically safe. This could be especially important to both new climbers who are anxious about the seemingly dangerous activity of bouldering as well as experienced climbers who have previously experienced pulley injuries and are thus aware and afraid of reinjury and the pain and rehabilitation that goes along with it. Finally, being scared or stressed on the wall can increase the danger associated with climbing, since smart decision making is key in this type of activity, so our device can help users be worried about one less thing while climbing and thus increase the psychological and physical safety of the climber. Overall, our product aims to keep users at peak physical and psychological condition and keep members of the climbing community healthy and safe.

Part B (Joshua)

During rehabilitation or injury-based-suspension, climbers rarely visit the climbing gym, nor do they go on outdoor climbing excursions as often. Unfortunately, this not only results in a pause of one’s favorite hobby and/or career (professional sport climbing ie. Olympic), it also steals away a social outlet. Typically, it is easier for one to meet others over shared interests, this is what makes a social outlet beneficial for making new connections. And when a climber loses this social outlet, they’re either forced to find another, or wait until they can use it again. CLIMB aims to mitigate this scenario. No climber should have to suspend themselves from the climbing gym or their outdoor excursions with friends. By preventing the most common injury in climbers (pulley injuries), our product aims to create a world where climbers don’t have to worry about an accident taking away their main social outlet.

Besides this scenario, our product does not have any other social influence. Our product’s main use-case is for pulley-injury prevention and rehabilitation in rock climbers. The only social implication of a pulley-injury is the indefinite suspension from a favored social outlet. This product does not meet the needs of other social factors because it specifically aims to improve an individual’s safety and welfare, regardless of social standing.

Part C (Jubahed)

There are many ways that this product can make economic impacts via its production, distribution and/or consumption. One main scenario that comes to mind is the financial incentives on the side of a fitness business, more specifically a gym that offers climbing services or a club/society for climbers. Through the widespread use of our product, these businesses can more easily attract new customers, as well as retain existing ones. Firstly, because our device is aimed toward injury mitigation, the potential fear of getting hurt through climbing will lessen, therefore making interested people more likely to make the jump toward purchasing a membership. Secondly, many climbers may consider quitting or significantly reducing their frequency to climb if injured. However, with increased ease of rehabilitation through our product, I can see this injury window being smaller, therefore encouraging climbers to retain their relevant memberships to these gyms.

Other economic benefits through our product are related to the broader society, outside of the fitness / personal wellness industry. Firstly, by simplifying and increasing access to reliable rehabilitation for injured individuals, we could potentially lessen the financial load with respect to healthcare services. So, an injured person can save money by needing less professional rehabilitation. Also, because this product could shorten the rehabilitation process, an injured individual could end up needing less time off from their day-to-day work, potentially increasing their economic productivity and prosperity.

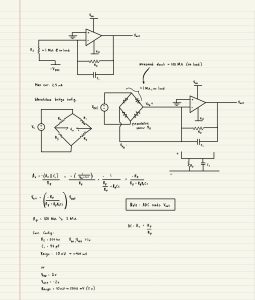

2. Sensor setup & ADC setup & sensor calibration (further testing required) (7hr): After constructing the recomended circuit in the A301-100 datasheet, to obtain -Vref and Vsupply, where Vref == Vsupply, I used two power supplies, one supplying 0.5V and -0.5V. Then, I hooked on a multi-meter to the Vout of the op-amp and pressed on the sensor with varying force to observe the output change. I did observe a change, however, Vout reached 0.5V with insignificant force. Realizing that I needed to modify the circuit to allow for a larger voltage range and tune the gain accordingly, I requested Alex’s help, for which he computed and provided me with the proper component values necessary to achieve this. After testing, the sensor functioned as predicted, and we we’re able to obtain readings ranging from 0 – 2V, where grams of force correlated with mV of change and extreme force encroached on 2V.

2. Sensor setup & ADC setup & sensor calibration (further testing required) (7hr): After constructing the recomended circuit in the A301-100 datasheet, to obtain -Vref and Vsupply, where Vref == Vsupply, I used two power supplies, one supplying 0.5V and -0.5V. Then, I hooked on a multi-meter to the Vout of the op-amp and pressed on the sensor with varying force to observe the output change. I did observe a change, however, Vout reached 0.5V with insignificant force. Realizing that I needed to modify the circuit to allow for a larger voltage range and tune the gain accordingly, I requested Alex’s help, for which he computed and provided me with the proper component values necessary to achieve this. After testing, the sensor functioned as predicted, and we we’re able to obtain readings ranging from 0 – 2V, where grams of force correlated with mV of change and extreme force encroached on 2V.