Accomplishments

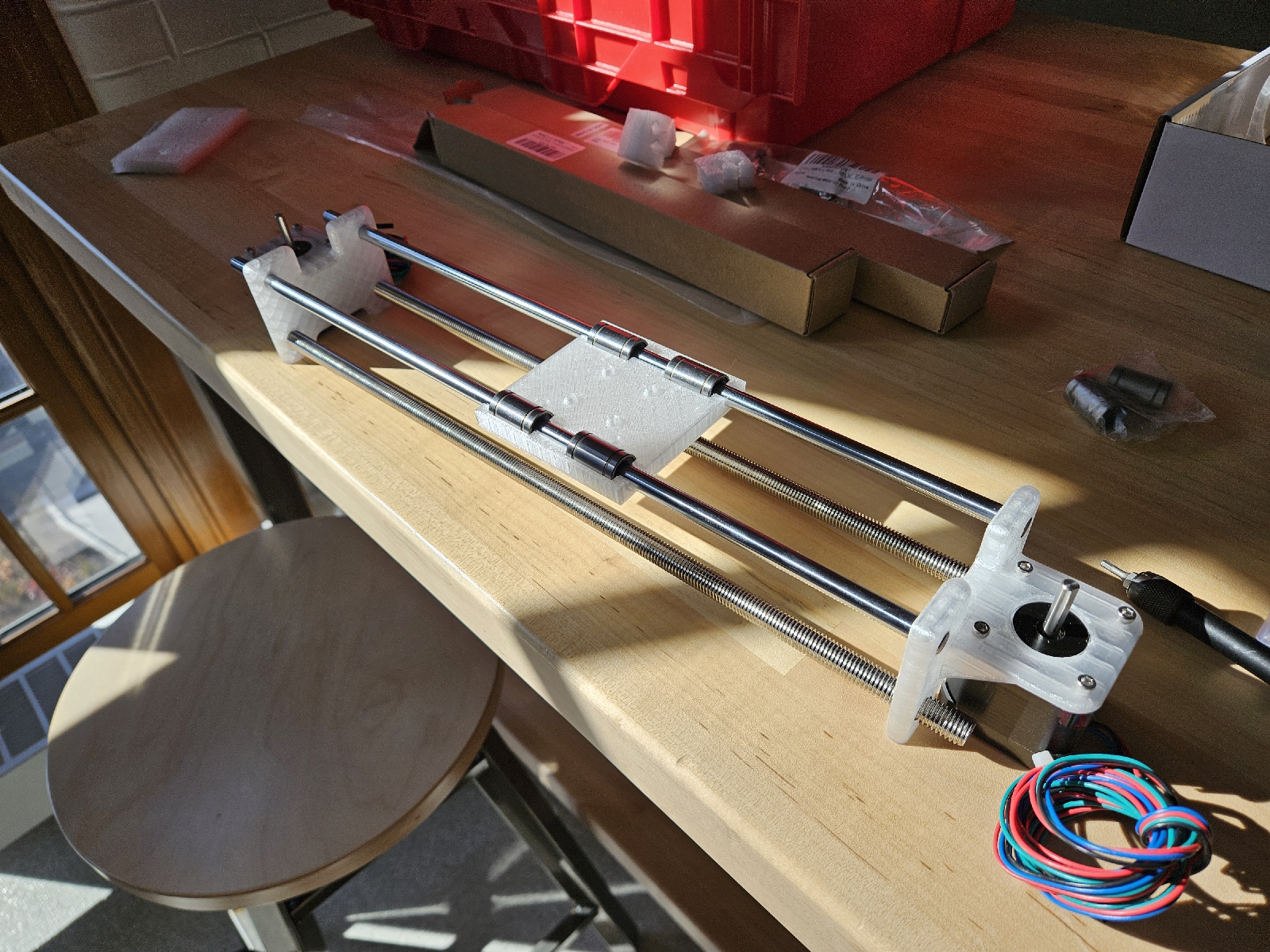

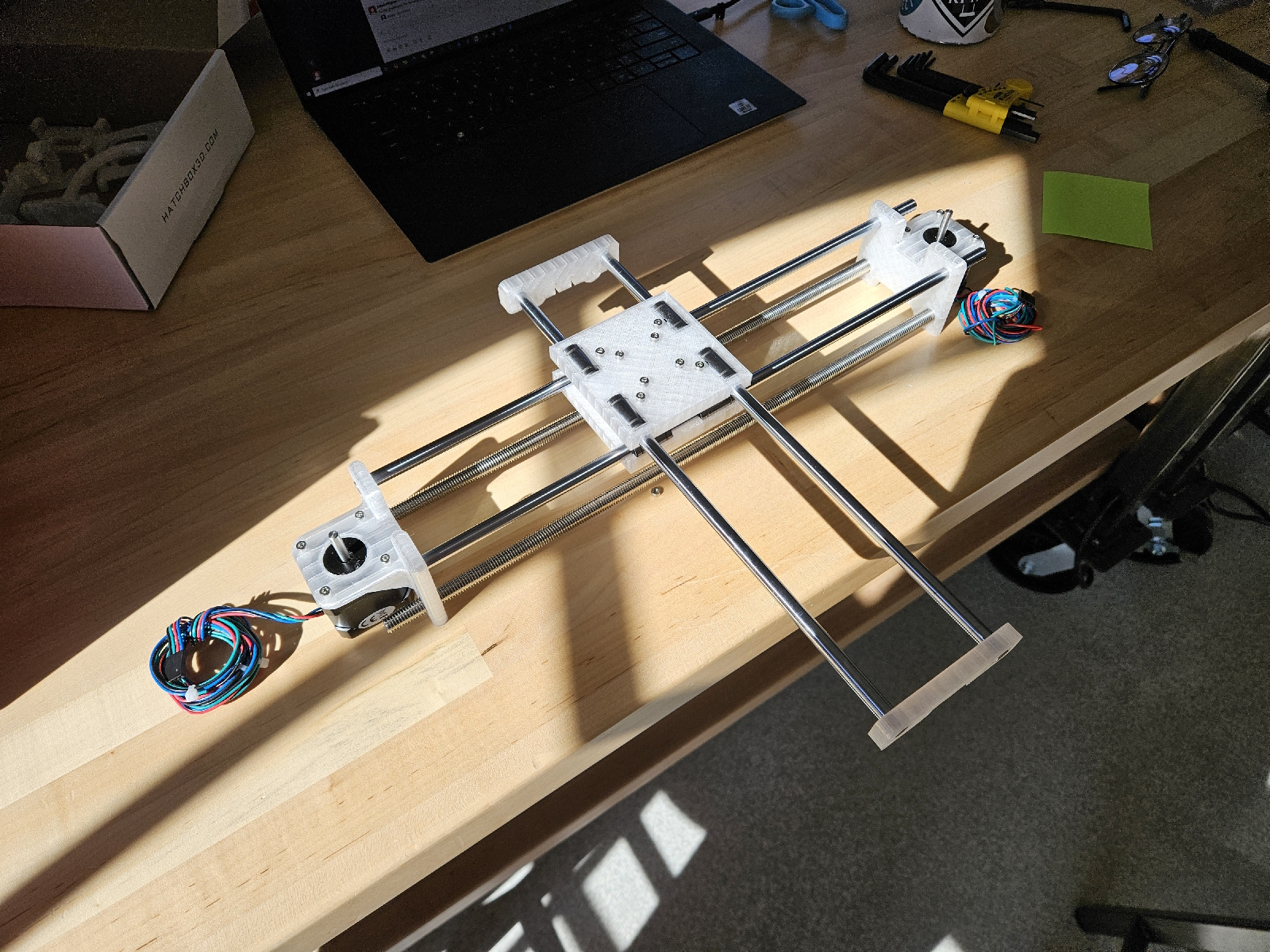

Robot construction is finally commencing! I made significant headway into assembling the various parts while following along the online guide. One speedbump I ran into was the diameters of the holes on some of the printed parts. For several mounts, the 8mm smooth rods (on which the XY motion relies upon to slide) were too large to fit, and so I had to spend time sanding the insides of the holes to properly fit the rods. The silver lining is that the rods can then be press-fit and don’t require extra fasteners. Additionally, due to the nature of 3D-printing, the small screw holes are also not an exact print, and so it took time to drive the screws through each hole and make grooves/widen the hole.

Progress

At this point, the bulk of the frame is put together, and now comes the task of adding the control mechanisms, such as the belt, pulleys, and servo motor wires with the Arduino. Following this, calibration and testing of the system can commence.