Accomplishments

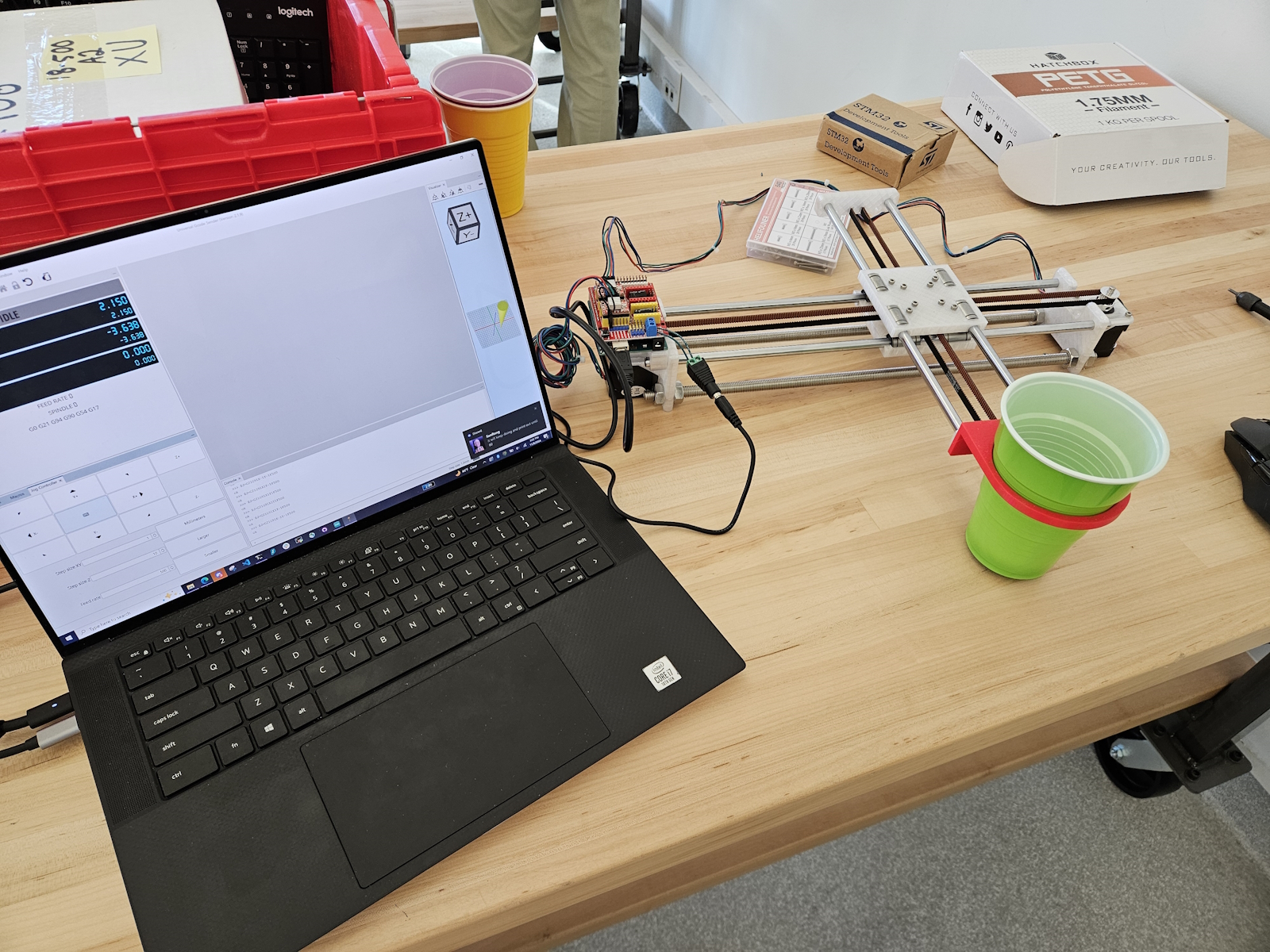

The robot moves! With the timing belt and pulleys in place, I mounted the Arduino, CNC shield, and motor drivers to control the steppers. After some difficulties while testing the stepper motors, I eventually came to several conclusions. The first is that the motor drivers (which plug into the CNC shield, which itself is plugged into the Arduino) are HIGHLY sensitive to electrical interference. Even lightly touching a driver can result in stalled motor motion. Later, online resources suggested to unplug the 12V 2A power supply before changing any connections with hot wires. I was very confused and at times exasperated when the motors would grind to a halt seemingly arbitrarily, and I suspect this issue to be a result of the two factors at the same time. I got GRBL (a free, open-source firmware that controls the motion of CNC machines, short for “G-Code Reference Block Library) uploaded to the arduino, and can send G-Codes through an external Universal G-Code Sender that controls the stepper motors in tandem. While I didn’t get a ton of time to play with it, it appears to be very powerful.

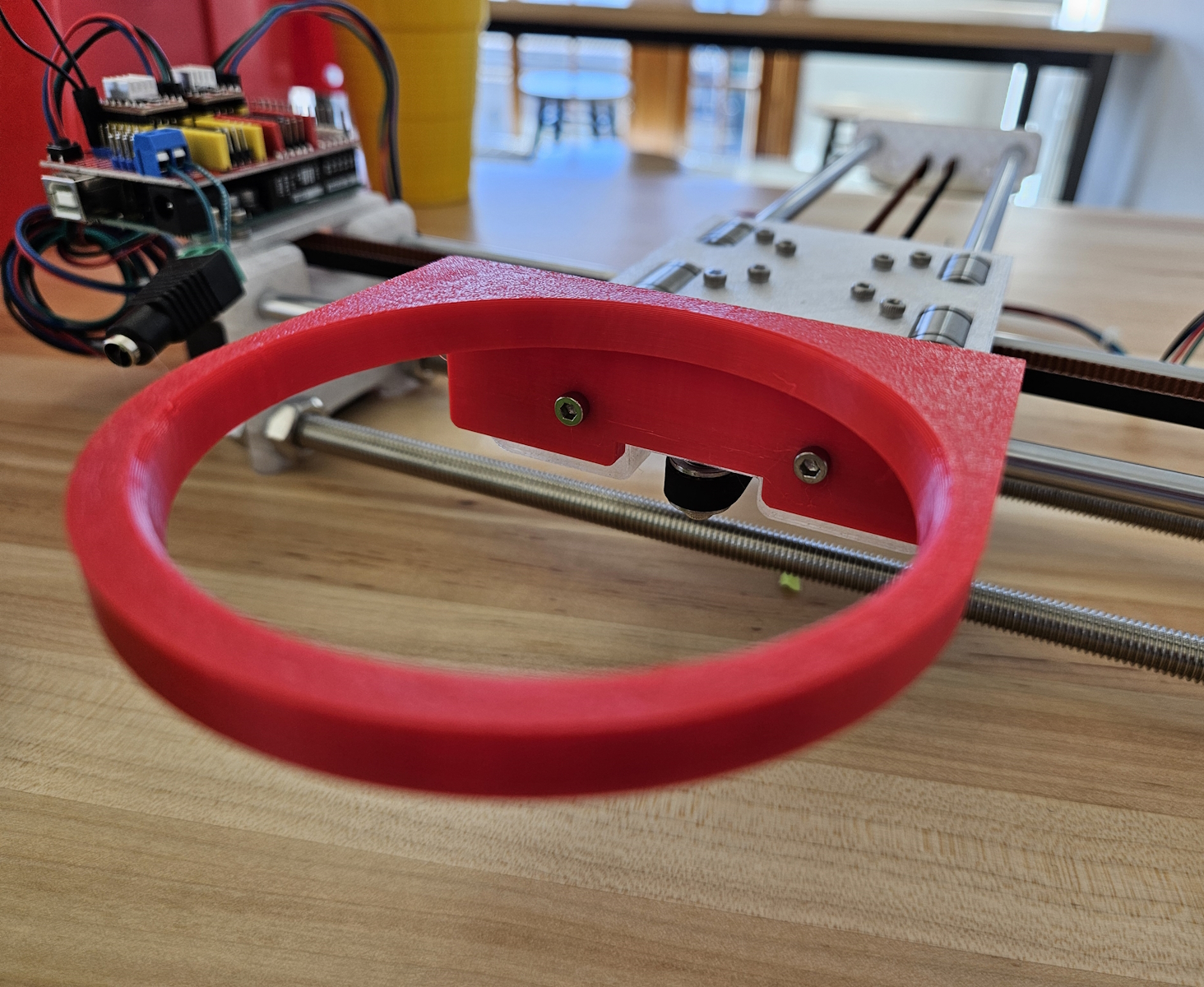

On another note, I had to do a small modification to the cup mount to accommodate for a belt bearing. The bearings slightly stuck out, and so I made a small cutout of the existing part. As bonus, I totally nailed the design of the cup mount. The cup is held just slightly above the surface of the table!

Progress

I expect to familiarize myself better with the XY robot controls, and see if I can send a single command to make it move to a specific location XY location. I did see a “set origin” button in the G-Code sender, so I believe this will be possible. In the future, I will also want to procure a soft material to line the cup mount, as the stepper motors can vibrate the entire system quite loudly. This will dampen the cup vibrating on the mount, which can be very loud.