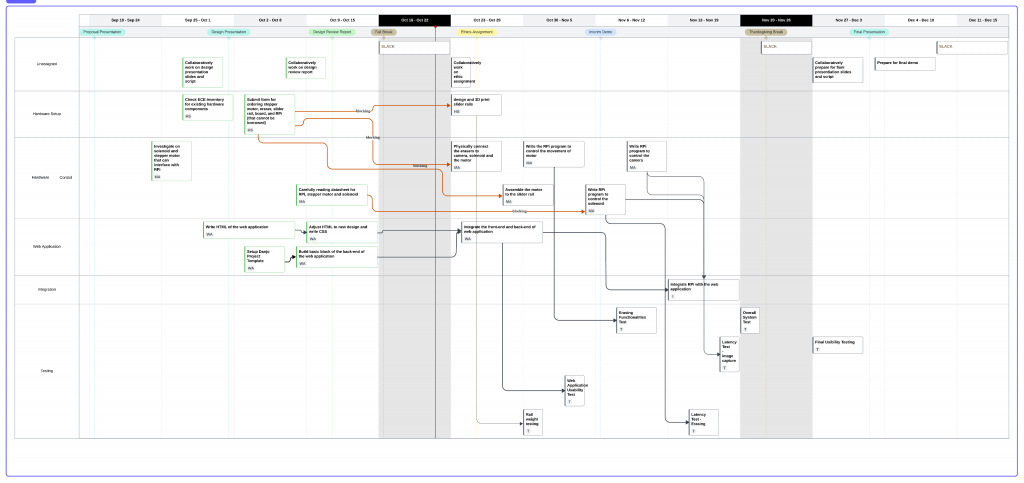

This week, all the team members worked together to complete the overall system test with 3 instructors and test the performance of the system a few more times with different speeds to figure out the speed that’s most stable to be used during the final demo. Since we have completed all the design and build of our system, the most significant risk at the current stage would be unexpected damage to the physical components. Therefore, we would be particularly careful during the testing and ensure the motor is not overheated and the current and voltage supplied would not exceed the corresponding value on the data sheets that damage our motor driver or motor.

There has been no change made to the design of our system during the past week.

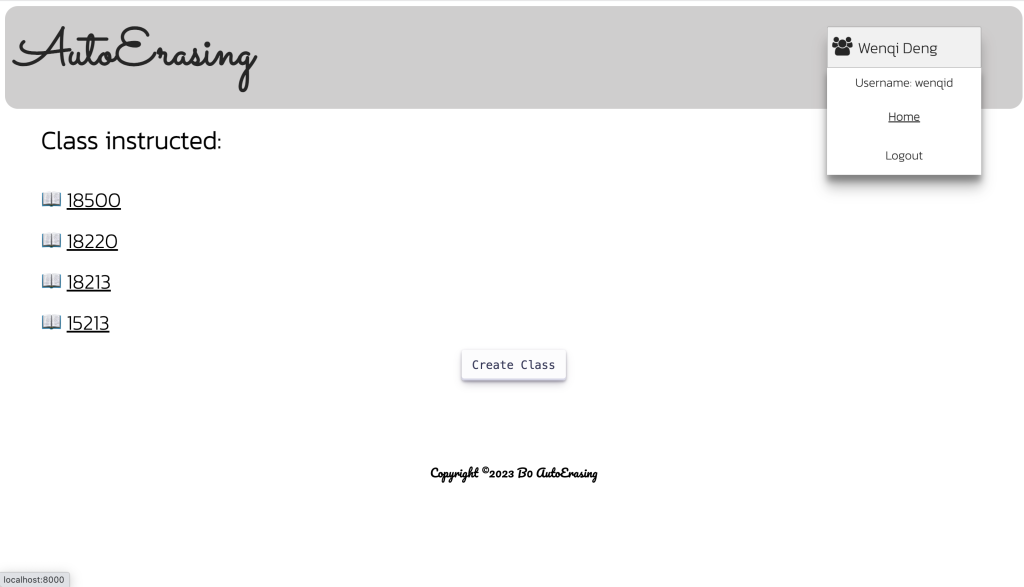

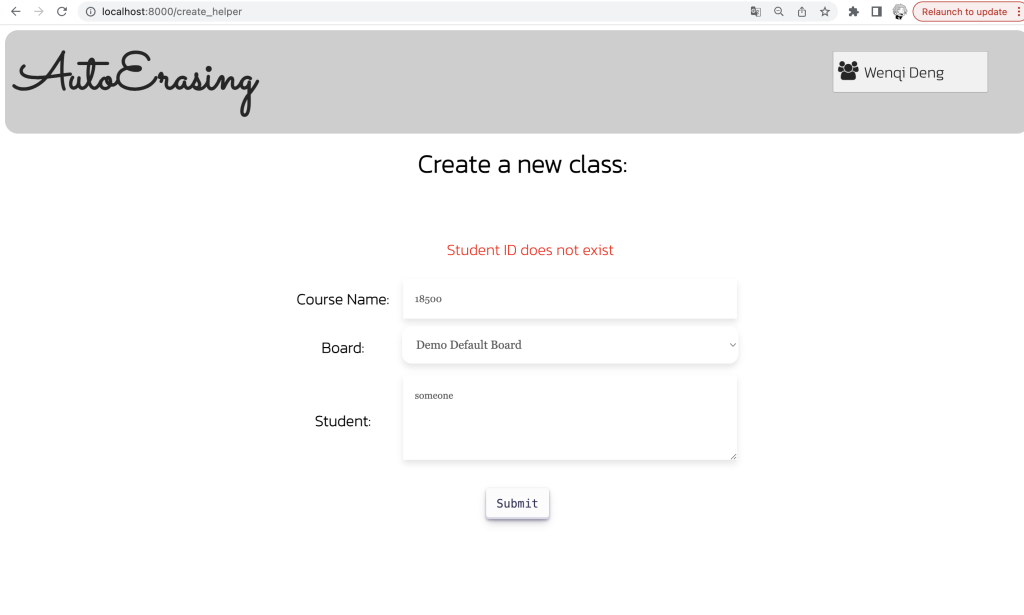

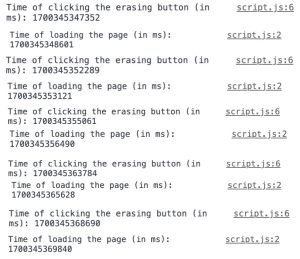

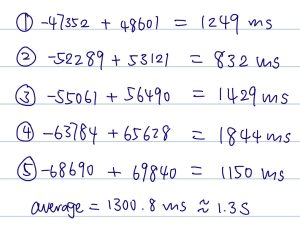

The unit tests we have carried out include latency tests for both erasing and image capturing, the user test of the website, and the power consumption test. In addition to that, we have completed the overall system test with 3 instructors and 3 students. From the latency test, we found the time taken for erasing a 30’’x 15’’ area of board takes 50s and the captured image should be displayed in 1.3s. From the power consumption test, we found that the peak power of our entire system is 50.65W. From the user test of the website, we have identified several confusing elements and the lack of instructions on the website, so we have modified the nav bar as well as added different instructions for both students and instructors on their home pages. From the overall system test, we have received feedback that the latency of the erasing board is a bit too large. For this reason, we are still exploring the peak speed our system can achieve while ensuring its stability. Other than that, we have also received feedback from Prof. Yu and Prof. Mukherjee that there are some glares in the images, so we will also find an optimized location to place the camera by adjusting its relative height to the board to avoid this issue.