In the past two weeks, our team spent most of our time adjusting our design and writing our design report. After further discussing the use case with Professor Yu, we have decided to shift our objective to build a “virtual board” that provides unlimited board space and decided to include the camera and projector in our project so students and instructors can access pictures of content after erasing it, and instructors can project the erased content back to the board.

In addition, after discussing our design with Professor Mukherjee, we realized that the hex-shaft wheels we chose would not work well with our D-shaft stepper motors, and we needed to include motor drivers and mounting hubs in our design. Moreover, we needed to reconsider the options of slider rails that will be incorporated into our design, since it might be hard to 3D print the slider rails with a length longer than 12 inches. Therefore, we spent a lot of time investigating parts with dimensions that match with each other and meet our requirements, and came up with a new list of materials. With those updated details, we have created our new design diagram and updated block diagram, placed orders for the new parts we found, and adjusted our schedule accordingly.

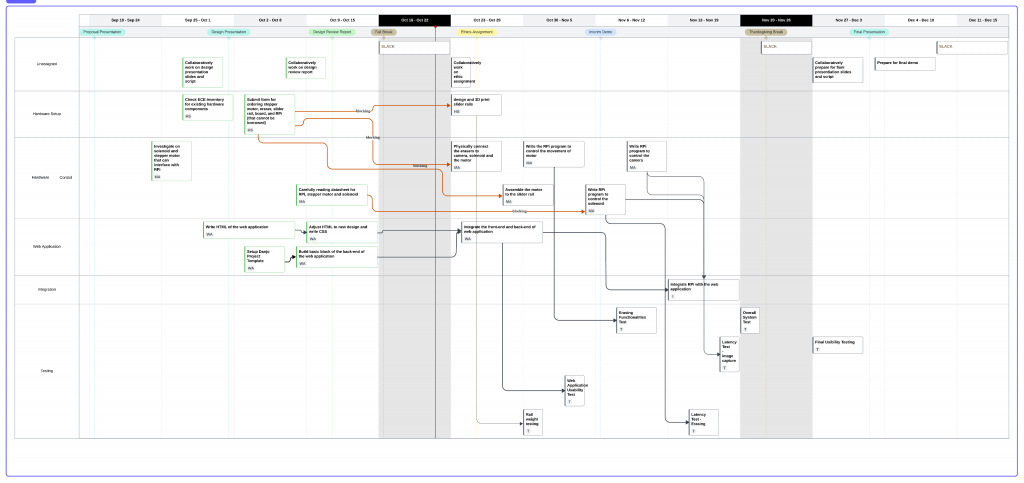

Since we have made a lot of changes during the past two weeks, our schedule has become slightly more packed with more additional tasks about the new features than we originally planned, which might slow down our progress in the future. The team members have decided to invest extra time during the next few weeks to set up the physical attachment and catch up with the progress to mitigate the cost.

For now, the most significant risk we identified that could jeopardize the success is we are still not sure whether our slider rail choice would fit well with the rest of the parts given that even thought the dimension matches, we need to ensure it’s strong enough to hold the other components. We planned to check out the struts at Tech Spark, but found that Tech Spark is closed during the fall break. We have also discussed the available options online but found out that the U-shaped channels that match the width of the wheels are either too high or too long for our design. We have decided to go with an aluminum U-channel that is longer than the dimension of our board and manually cut it at Tech Spark. To mitigate the risk, we have selected a few other channels that are slightly wider than we expect as backup options, and decided to place the order and pick them up as soon as possible at Home Depot if our original plan fails.