- This week I mostly worked on meeting with my teammates and TA/Prof. to make an update to the physical part design to ensure it’s more reliable. We’ve made a quite big change to pivot from the previous mechanical design of moving the wheels horizontally to using a screw motor so that its movement won’t be heavily affected by the friction between the board and erasers. I also worked on writing and discussing ethics assignment with my teammates and working on the webapp development.

- My progress is a little behind schedule because we plan to get started with building the physical parts but now we have an updated plan. I will work more on webapp development and integration this weekend to leave more time for physical parts assembling next week.

- We plan to start our first iteration of building the physical part of erasing and testing the motor control code out and revising the implementation based on testing result.

Wendy’s Status Report for 10/28

During the past week, our team has met a lot to discuss the feedback we received for the design report and redesign of our system. After realizing the risk of using a slider rail and wheels to control the movement of erasers, we decide to use a linear actuator with a screw rod so the friction won’t impede the movement of the wheels, and submitted the ordering form for the new parts. Personally, I have spent a significant amount of time researching existing stepper motor linear actuator options online and how they function in different systems, and redrawn a detailed design diagram during the past week. Moreover, I continue working on the frontend of the web application and investigating the functionalities of the camera. I have also reflected on the ethics readings to finish the ethics assignment.

Currently, my progress is on schedule. I and Jiayi are working together on integrating the front-end and back-end of the web application, and aim to demonstrate a functioning web application that can call backend functions after interacting with it on the frontend at the group meeting of the following week. However, due to the shift of the design, there is a delay in the arrival time of our parts, so the team’s progress in assembling the parts to the board is a little behind. To catch up with the project schedule, we plan to finish as much code as possible before the parts arrive, so we can quickly move to build the physical attachment and test our code once the parts have all arrived.

Team Status Report for 10/28

The most significant risk we have currently is about the mechanical design of the erasing system. After discussing with professors, we realized that the friction between the side of the rails and the wheels might prevent the wheels from moving. We will address this risk by adjusting the pressure applied on erasers, which is causing the friction between rails and wheels. We also identified some back up plans, in case the original design would not work. One is to make the wheels rotate vertically to the board, but this design might also face the issue of friction caused by gravity. Another more promising back up plan is to use a screw rod with non-captive stepper motors, but the shipping time of the components is long.

We made several changes to our current design. First is that we decided to remove the solenoid from our design, as a trade-off between functionality and stability. We think that erasing only part of the board, which is what solenoids are for, does not add too much to use case. On the other hand, solenoids add much risks and vulnerability to our physical design, because of the sudden push or pull force it exerts on the whole system. Second is that we decided to modify the eraser moving mechanism as described in the last paragraph. We now have 3 plans, and we will test each plan to see which one works best.

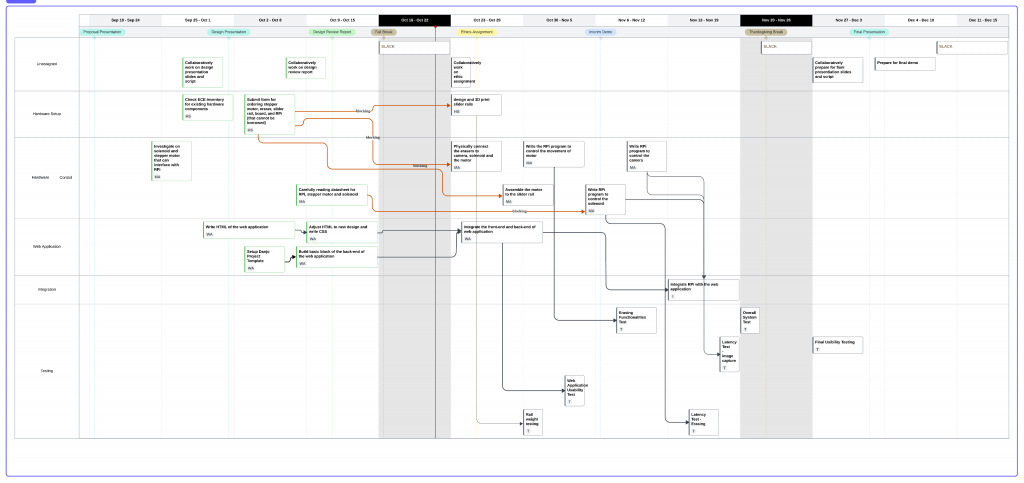

In response to those changes, we modified our schedule. First, the solenoid task is removed. Second, due to shipping delays, we postponed the task of building the mechanical system. We are unsure of when things will actually be delivered, but we will be working on other available parts of the project, while waiting for things to arrive.

Xiaoyu’s Status Report for 10/28

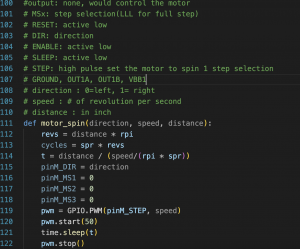

In the past week, our team further modified the eraser moving mechanism. . I spend some time online researching about different types of stepper motor with rods and we decided to switch to non-captive stepper motors for our design. I looked for appropriate motors and screw rods and we made some new orders and are now waiting for things to arrive. Personally, I have now write some simple Rpi code to control the movement of the motor through motor driver for unit testing. Below is a screenshot of some code

.

Due to delays of shipping and changes of design, our team might not be on schedule in terms of the physical part of our design. We are trying to make this up by working on the code portion of our design. We will also devote more time once our orders arrive.

Next week, our schedule heavily depends on when things arrive. We are planning to start building out system on whiteboard. Personally, I will be integrating the unit code I wrote into the whole design system. I will also be setting up Rpi and start unit testing the functionality of motor.

Jiayi’s Status Report for 10/21

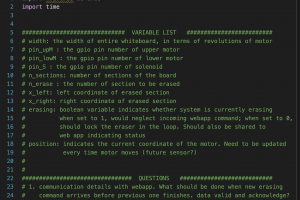

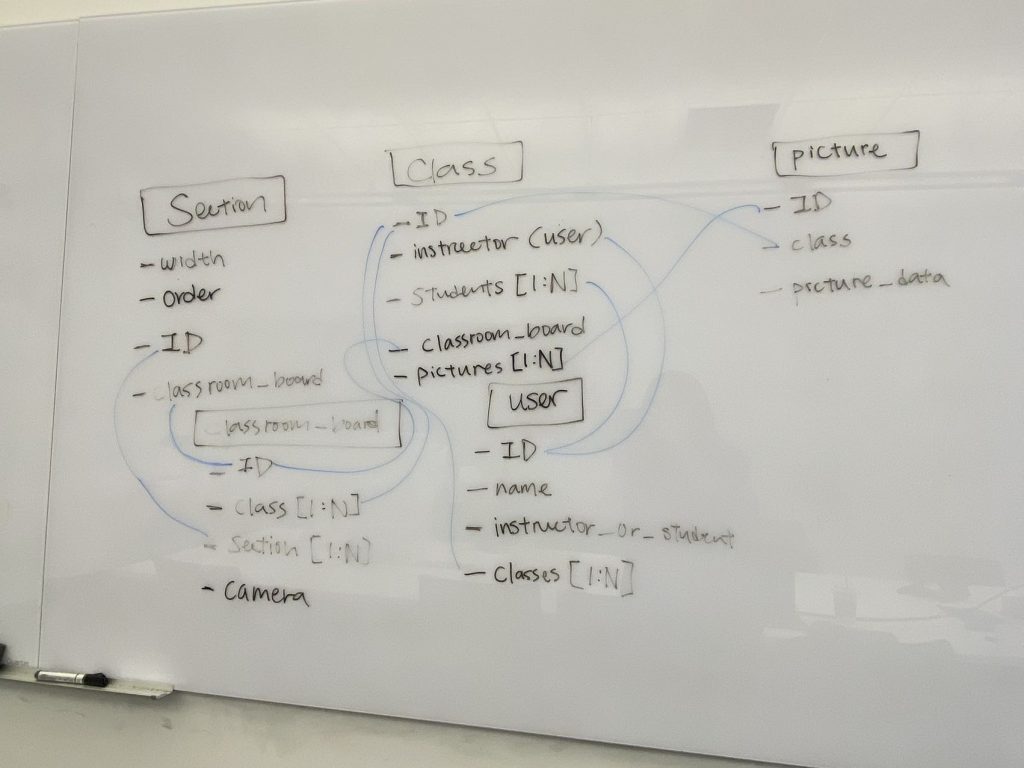

In the past two weeks, I mostly worked on revising the design with my teammates and working on the web app backend. In addition to the design report, I’ve also worked with Wenqi to design the model to use in our database.

My progress is on schedule as there’s nothing planned for fall break and I got some time to catch up with the pace of web app development. This week I also started putting the code together with Wenqi. In addition, our team has ordered components and is getting ready to assemble the parts together once they arrive next week.

So our primary deliverables to complete next week would be to put the communication between the backend and frontend together and build the physical components together.

Weekly question:

As we’re getting started on planning the actual physical parts, I’ve searched online in detail with my teammates to look for different types of motors, slider rails, shafts, and mounting components. In addition, I’ve also started looking into how webapp can communicate with RPi.

Xiaoyu’s Status Report for 10/21

These two weeks we basically worked on writing the design report. Based on feedback and discussion with professors, we decided to rewrite our use case. Also, we added a lot more design details about how we would connect each components physically. We ended up ordering many new components for the project. Personally, I am staring to set up Raspberry Pi and wrote some pseudo code. I now have some overall idea about how my code would look like, but I still need to learn how to send correct signals to stepper motor drive. Below is a screenshot of part of the pseudo code.

Due to changes in our design, we ended up ordering some new components during mid-semester break, which might arrive later than expected. Some of my code would need to depend on the components, so my schedule might be behind. However, I am planning to start writing code about whatever I have now, and spend some extra time fixing everything once our new orders arrive.

Next week, after the components arrive, our team will be spending much time on physically building the system and adjusting it. Personally, I will also continue to write motor and solenoid control code.

In response to the weekly question, I am learning to use Raspberry Pi for this project. I’ve had previous experience with Arduino and Nucleo microcontrollers, so I expect that learning to use RPi would not be too difficult. Another thing that I need to learn is to use stepper motor driver, which might differ from regular DC motor drivers that I used before.

Wendy’s Status Report for 10/21

For the previous two weeks, I spent most of my time refining our design, researching new parts, and writing our design report with other team members. Since we have received a lot of feedback from the professors and our TA, there are a lot of changes we need to make in our design report. Individually, I have also redesigned the prototypes of the web application in response to the changes, created and adjusted the block diagram and some of the design diagrams, and investigated how to incorporate the camera module into our system. In addition, after making changes in the HTML and CSS files, I and Jiayi have discussed how to set up the Django models of our web application and started integrating the backend and frontend of the web application.

Currently, my progress is on schedule. However, since there are a lot of new tasks added to the adjusted schedule, I will make extra commitments next week to ensure that I will not be behind the schedule in the future. I will spend most of my time integrating backend functionality with my frontend interface and plan to finish integrating most of the features and polish the CSS to make the user interface easier to use. In addition, I will work with other team members to complete the ethics assignment and set up the physical attachment after our parts arrive.

To accomplish our planned tasks, I will need to learn a lot about hardware assembly and motor control. Since I have little prior experience in robotics, I didn’t realize there are so many details we need to take into consideration while designing our system. In addition, the tool I am learning right now is the IP camera we will use in our system, including how to send commands from the backend of the web application to capture an image and adjust its pan and tilt through ONVIF protocol.

Team Status Report for 10/21

In the past two weeks, our team spent most of our time adjusting our design and writing our design report. After further discussing the use case with Professor Yu, we have decided to shift our objective to build a “virtual board” that provides unlimited board space and decided to include the camera and projector in our project so students and instructors can access pictures of content after erasing it, and instructors can project the erased content back to the board.

In addition, after discussing our design with Professor Mukherjee, we realized that the hex-shaft wheels we chose would not work well with our D-shaft stepper motors, and we needed to include motor drivers and mounting hubs in our design. Moreover, we needed to reconsider the options of slider rails that will be incorporated into our design, since it might be hard to 3D print the slider rails with a length longer than 12 inches. Therefore, we spent a lot of time investigating parts with dimensions that match with each other and meet our requirements, and came up with a new list of materials. With those updated details, we have created our new design diagram and updated block diagram, placed orders for the new parts we found, and adjusted our schedule accordingly.

Since we have made a lot of changes during the past two weeks, our schedule has become slightly more packed with more additional tasks about the new features than we originally planned, which might slow down our progress in the future. The team members have decided to invest extra time during the next few weeks to set up the physical attachment and catch up with the progress to mitigate the cost.

For now, the most significant risk we identified that could jeopardize the success is we are still not sure whether our slider rail choice would fit well with the rest of the parts given that even thought the dimension matches, we need to ensure it’s strong enough to hold the other components. We planned to check out the struts at Tech Spark, but found that Tech Spark is closed during the fall break. We have also discussed the available options online but found out that the U-shaped channels that match the width of the wheels are either too high or too long for our design. We have decided to go with an aluminum U-channel that is longer than the dimension of our board and manually cut it at Tech Spark. To mitigate the risk, we have selected a few other channels that are slightly wider than we expect as backup options, and decided to place the order and pick them up as soon as possible at Home Depot if our original plan fails.

Jiayi’s Satus Report for 10/7

This week we mostly worked on the design presentation. In addition, I also spent some time reading the feedback thoroughly to understand what parts we are missing in our design to work on the design revision. In addition, I’m working on the webapp backend development. After setting up he framework, I’m spending time to start the coding on backend by building the general structure on interface with frontend, temporary interface with RPi.

I’m mostly on track to the schedule, and I will need to keep the pace on schedule by investing more time on the backend development.

Currently we’re mostly working on the basic logics of how information flows, but the mechanism for voting and for professors to decide which board to erase could be more complicated, so I will spend more time next week to get a decent amount of work done on the “voting + erasing” logic done.

Team Status Report for 10/7

This week, our team has spent a great amount of time working on finalizing the details for our first components ordering. While we worked on this, we realized some potential risks that could be more dangerous to our deliverables. This includes mostly the assembly of the physical board + eraser + wheel + rail + RPi. We need to ensure that the following aspects don’t fail:

- the power source should have enough voltage to support the motor, linear actuator, and RPi.

- the components aren’t too heavy to make the board not balanced.

- the communication between PRi and our web server should be generalized, and this part is the one that we haven’t addressed enough in our meeting this week and we decide to worry about the hardware parts for now and invest more time on RPi and web server integration after fall break based on our schedule.

For the first two components, we’ve searched for potential physical components that could give enough voltage while has a light weight. And we’ve successfully found the components and added it to our budget list. However, the rail we decided to spend some time exploring the 3D printing options as there isn’t a rail online that fits well to the wheel we found. Besides this, we currently don’t have major changes in our system spec. Due to the change, there is a slight decrease in our cost, but we will still need to check if we need to spend any money on the 3D printing.

Since the change is in system spec instead of how we design the process, there is no update on the schedule. Below is our current budget form.

To answer this week’s question, we’ve applied the following principles of engineering, science, and mathematics:

- during the solution formulation, we prioritized the approach that gives the most general capability while being of great familiarity to most group members. Therefore, we’ve utilized our knowledge in software engineering so that we could use the Django framework to manage the backend of our web app with access to relational DB that stores relevant information about the student’s “voting” mechanism in our project.

- We’ve also considered various types of motors and control systems with our background in embedded system engineering and decided to use stepper motors to have better control over the precision of movement.

- We also applied our knowledge in electrical engineering to come up with potential solutions to wire the components together so that we could reduce the cost of power sources by buying fewer batteries while supplying the voltage to more components.