Changes

- We have decided to use copper foil tape for the circuitry of the board, letting us more easily integrate the detection subsystem with the movement subsystem.

Progress Pictures

- Holes in pieces + a ferrous nut that will go inside each piece.

Changes

Progress Pictures

This week I worked mostly on the pieces and the planning of the board top. I created the full plans for the pieces, although the designs remain pencil-and-paper, but everything is laid out. Right now I am waiting for parts.

For the pieces, I drilled holes in them, found an appropriate material for the magnet to attach to, and am waiting for my order to keep working on it. Pics in the group report.

For the board top, I’m commissioning it from TechSpark woodshop and then drilling holes into it.

Risks

Changes

Schedule

Progress Pictures

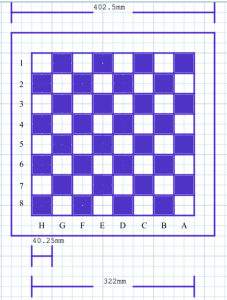

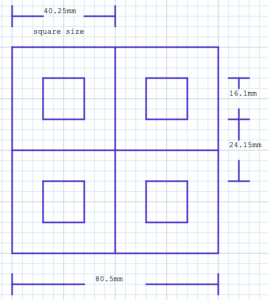

This week I paused work for the circuitry of the piece detection as I realized I needed to get the ball rolling on materials for the construction of the board asap. While I wait for stuff being ordered or made, I will continue to work on the circuitry. Specifically, I touched based with Tony and we made some new design desicions based on what we both have at the moment. We discussed the construction of the board top as well as constraints we must keep in mind when we put our subsystems together, and I have spent this week researching a bit more and preparing for putting orders in towards the construction of the board.

No updates to my schedule as of last week in terms of pushing anything back, but rather rearranging my tasks in order to pipeline them.

Risks

Changes

Schedule

Progress Pictures

This week I have been working on the detection circuit since the multiplexer arrived. I am able to loop through the inputs and will soon scale it to use all 16 inputs, adjusting the resolution as needed. Once the 16-piece detection circuit is working on the breadboard, I will begin construction of the board top or construction of the pieces, depending on when the pieces ordered from Amazon arrived. I mention wooden pieces because, as of our design revision, we will now be modifying wooden chess pieces instead of 3D printing our own.

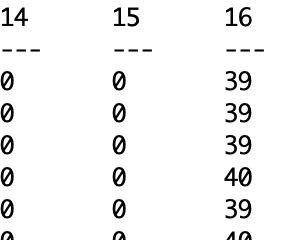

Below is an image of the arduino console detecting input from 3 “pieces”, where 14 and 15 were set to GND and 16 was set to an arbitrary voltage <5V:

I am behind our original schedule but proceeding well into the adjusted schedule.

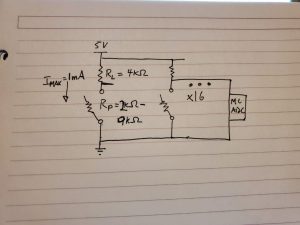

This week, I’ve procured everything necessary for the detector circuit minus a multiplexer. While I wait for that to arrive through the mail, I’ve been learning how to use the Dremel DigiLab 3D Slicer software to model our own pieces and print them in TechSpark. This is a simple circuit diagram of the detector circuit:

So far I’m still on schedule, and by next week I hope to have both the 3D printed pieces and a functioning prototype circuit.

No changes to the schedule have been necessary.

This week I settled on working with an Arduino and have gotten reacquainted with programming it so that once the circuit for detection the pieces is wired up, it will be easy to fine tune.

By next week, I hope to have that circuit built and tested and get ready to move onto the board top.

I am still personally on-schedule, but I will not be if I don’t pick up my pace and meet my expected deliverables for next week.