Progress and challenges:

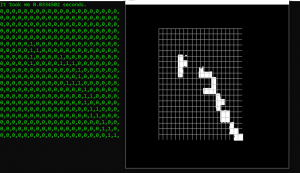

This week’s goal was to have a full 20×20 LED matrix constructed. The process of constructing the matrix includes cutting strips into sets of 20 LEDs and soldering them together. This step is necessary to form the matrix as the LED strip would not be able to bend and form a second row without wasting LEDs. After each 20 LED segment is attached to the matrix, it must be tested to make sure that it turns on properly. This is done by simply plugging in the power and seeing if all the LEDs still turn on.

As of 11:00 pm, I have only been able to connect 8 rows which is short of the 20 rows that I intended to have connected. The soldering process is rather tedious as each end of the LED rows have 4 connections. All connections have to be tinned prior to connecting. I have documented images of the process in this doc. The doc will be updated once more rows are added today.

Deliverables:

Because the matrix is not finished, this week’s deliverable is 8 rows of the matrix rather than an entire matrix that was scheduled.

Plan for next week:

The plan for the rest of the day is to continue soldering the rows together to prevent further schedule delays. For next week, a full matrix will be complete and installed into the Blokus board. I will work with Aria on the interface between the microcontroller and client software.